Inventory management is a crucial aspect of quality control in any manufacturing setting. By implementing a well-structured quality control shop inventory template, businesses can efficiently track, manage, and organize their raw materials, work-in-progress items, and finished goods. This comprehensive template ensures proper stock levels, minimizes waste, and facilitates traceability throughout the production process.

In today’s competitive manufacturing landscape, maintaining accurate and up-to-date inventory records is paramount for optimizing operations and ensuring product quality. A quality control shop inventory template provides a standardized framework for recording and monitoring inventory data, eliminating errors and enhancing data integrity. Moreover, it enables seamless integration with other quality control systems, such as inspection and testing procedures, providing a cohesive view of the production process.

Furthermore, using a quality control shop inventory template streamlines inventory management tasks, saving valuable time and resources. It minimizes the risk of overstocking or understocking, ensures timely procurement of raw materials, and facilitates efficient inventory replenishment. By eliminating manual data entry and automating inventory tracking, businesses can improve productivity and reduce operational costs.

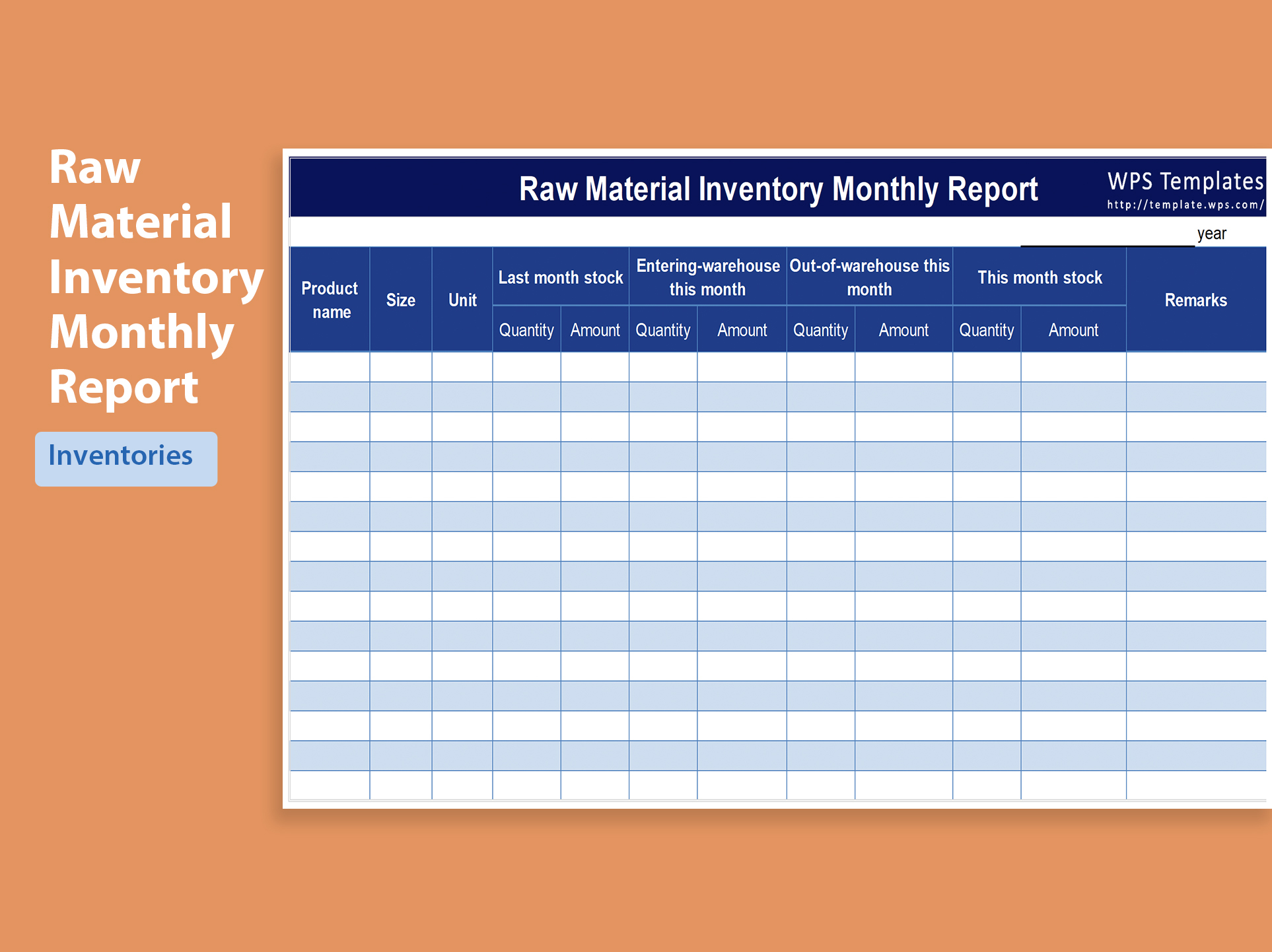

Components of a Quality Control Shop Inventory Template

Basic Information

The template should capture basic information about each inventory item, including its unique identifier (e.g., part number, serial number), description, quantity on hand, and storage location within the shop. This information provides a clear overview of the inventory and its distribution.

Additionally, the template may include fields for recording the item’s supplier, purchase date, and expected delivery time. This data helps track inventory movements and facilitates coordination with suppliers, ensuring timely replenishment.

Quality Control Parameters

A critical aspect of the quality control shop inventory template is the inclusion of quality control parameters. These parameters may include inspection criteria, acceptance limits, and testing procedures. By documenting these parameters, the template ensures that all inventory items meet the established quality standards before being released for production or shipment.

The template can also incorporate a section for recording inspection and testing results. This section provides a historical record of the quality checks performed on each inventory item, enhancing traceability and ensuring accountability for quality compliance.

Inventory Management Information

To optimize inventory management, the template should include fields for recording inventory movements, such as receipts, withdrawals, and adjustments. This information helps track inventory levels in real-time and facilitates accurate stock reconciliation.

Moreover, the template can incorporate reorder points and safety stock levels for each inventory item. These parameters help prevent stockouts and ensure uninterrupted production while minimizing the risk of overstocking and associated storage costs.

Benefits of Using a Quality Control Shop Inventory Template

Implementing a quality control shop inventory template offers numerous benefits for businesses, including improved inventory accuracy, enhanced quality control, streamlined operations, and reduced costs.

By providing a structured approach to inventory management, the template minimizes errors and ensures consistent data entry. This accurate inventory data supports effective decision-making and helps businesses optimize their inventory levels, reducing the risk of shortages or excess stock.

Furthermore, the integration of quality control parameters within the template ensures that inventory items meet the required specifications. This proactive approach to quality control reduces the risk of defective products entering production or reaching customers, enhancing product quality and customer satisfaction.