Embarking on any project involving heavy lifting requires meticulous planning and clear communication. That’s precisely where a comprehensive lifting equipment scope of work template becomes an invaluable asset. This document isn’t just a formality; it’s the backbone of a safe, efficient, and successful lifting operation, ensuring everyone involved understands their roles, responsibilities, and the precise parameters of the task at hand.

Think about the complexities involved: precise load calculations, intricate rigging plans, stringent safety protocols, and the coordination of multiple teams and specialized machinery. Without a well-defined Scope of Work (SOW), even the simplest lift can become a chaotic and potentially hazardous undertaking, leading to delays, cost overruns, and, most critically, safety incidents.

A good template helps you systematically address every facet of the project, from initial assessment to final execution. It acts as a universal language for project managers, engineers, operators, and safety personnel, guaranteeing that all parties are aligned and working towards the same goal with the highest standards of safety and professionalism.

Why a Detailed Scope of Work is Critical for Lifting Operations

When you’re dealing with immense weights and specialized machinery, the stakes are always high. A well-crafted Scope of Work for lifting operations isn’t just a suggestion; it’s an absolute necessity. It lays out a clear roadmap, minimizing ambiguity and ensuring that every person on the job site understands exactly what needs to be done, how it will be done, and who is responsible for each step.

Imagine a scenario where a critical piece of equipment needs to be moved. If the SOW isn’t clear on the exact lift path, the specific crane to be used, or the safety zones, you’re inviting confusion and potential danger. A detailed SOW clarifies expectations for all stakeholders, from the client requesting the lift to the crane operator on the ground, preventing misunderstandings that could lead to costly mistakes or, worse, serious accidents.

Ensuring Safety First

Safety is, without a doubt, the paramount concern in any lifting operation. The SOW acts as your primary safety document, outlining all the necessary precautions, risk assessments, and emergency procedures. It should clearly define the safety personnel involved, required personal protective equipment (PPE), communication protocols during the lift, and what steps to take if something goes wrong. This proactive approach to safety is what truly protects lives and assets.

By detailing every potential hazard and the corresponding mitigation strategies, you create a culture of safety where everyone is aware and accountable. This isn’t just about ticking boxes; it’s about embedding safety into the very fabric of the operation, making it an inherent part of the planning and execution process.

Streamlining Project Execution

Beyond safety, a robust SOW brings incredible efficiency to your project. It helps in scheduling resources effectively, predicting timelines accurately, and allocating budgets with precision. When all the necessary equipment, personnel, and permits are identified and detailed upfront, the likelihood of unexpected delays or additional costs significantly decreases. This level of organization allows for smoother transitions between project phases and keeps the entire operation on track.

It also serves as a benchmark for quality control. With clearly defined deliverables and performance indicators, you can consistently monitor progress and ensure that the lifting operations meet the specified standards and the client’s expectations. This proactive monitoring helps in identifying potential issues early and addressing them before they escalate.

Managing Risks and Compliance

The regulatory landscape for lifting operations can be complex, involving various local, national, and international standards. A comprehensive SOW helps you navigate these requirements by documenting all compliance measures, certifications, and permits. It acts as a verifiable record that demonstrates your adherence to industry best practices and legal obligations, protecting your organization from potential liabilities.

Furthermore, it facilitates robust risk management. By identifying all potential risks – from environmental factors like wind speed to mechanical failures or human error – and planning specific contingencies, you build resilience into your operation. This foresight allows you to react quickly and effectively to unforeseen circumstances, minimizing their impact and ensuring the overall success of the lift.

Key Elements to Include in Your Lifting Equipment Scope of Work Template

Building an effective lifting equipment scope of work template means including all the critical details that define the project from start to finish. This document will serve as the single source of truth for everyone involved, so its completeness and clarity are paramount. Let’s look at the essential components you’ll want to incorporate to ensure nothing is overlooked.

A well-structured template will guide you through the process of detailing everything from the basic project information to the intricate operational procedures. It helps in capturing all the nuances that might otherwise be missed, providing a solid framework for planning and execution. This methodical approach is key to achieving consistent success in your lifting projects.

When you’re putting together your lifting equipment scope of work template, make sure it addresses these crucial areas:

- **Project Overview and Objectives:** Clearly state the project name, identification number, client details, and the primary goal of the lifting operation. What needs to be moved, where, and why?

- **Site Information and Conditions:** Describe the physical location of the lift, including access points, ground conditions, potential obstructions, overhead hazards (power lines, structures), and any environmental considerations (wind, temperature).

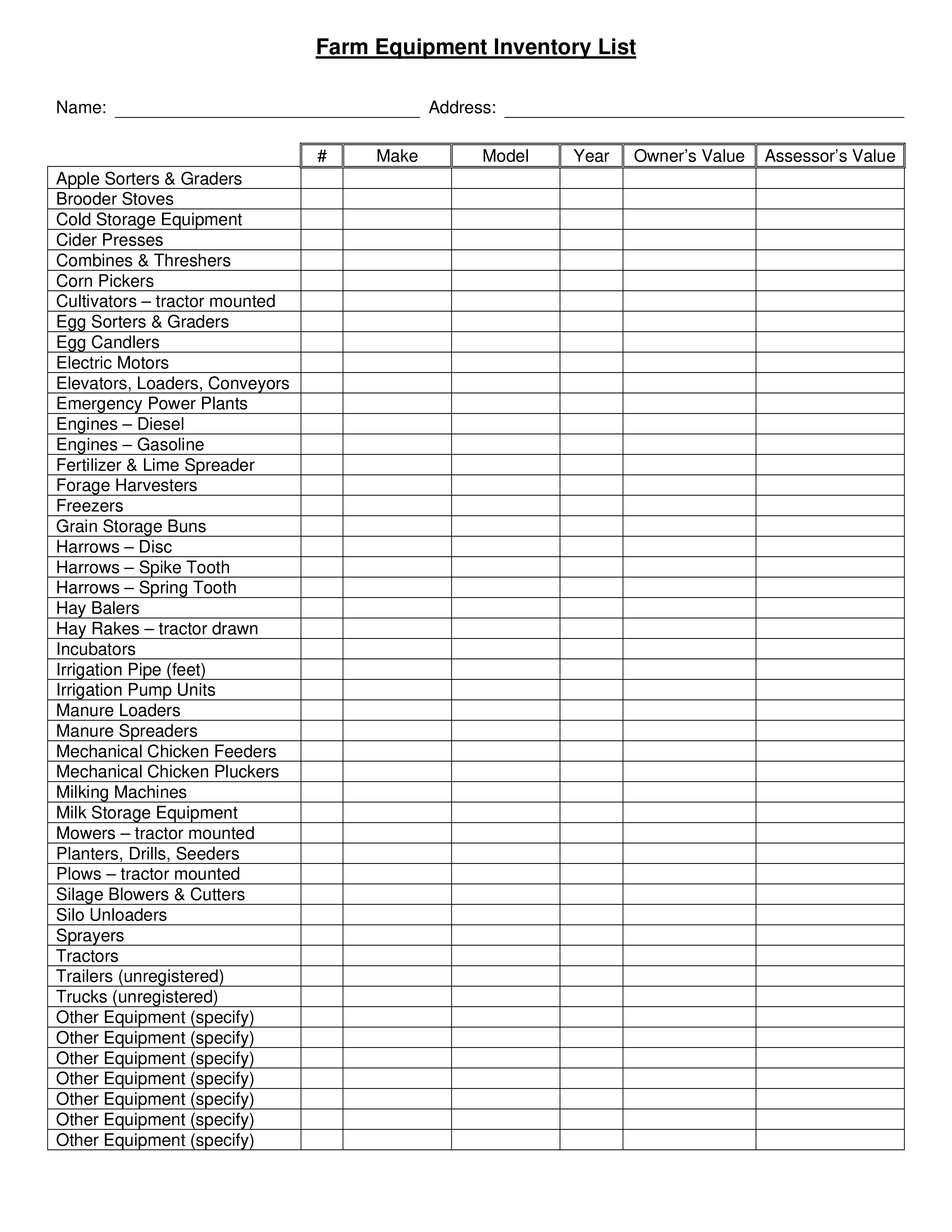

- **Equipment Specifications:** Detail all lifting equipment to be used, including type of crane, hoist, rigging gear, and accessories. Include their capacity, certification details, inspection records, and maintenance schedules.

- **Personnel Requirements and Qualifications:** List all personnel involved (crane operators, riggers, signal persons, supervisors, safety officers) and outline their required certifications, licenses, and experience levels.

- **Lift Plan and Procedures:** This is the core of the SOW. Describe the step-by-step lifting procedure, including load weights, lift radius, rigging configurations, communication methods, and specific sequences of operations.

- **Safety Protocols and Risk Assessment:** Document all identified hazards, the corresponding risk assessments, and the control measures to mitigate them. Include emergency response plans, first aid provisions, and specific safety briefings.

- **Timeline and Schedule:** Provide a detailed schedule for the entire operation, including mobilization, setup, execution of the lift, demobilization, and any contingency time.

- **Communication Plan:** Outline how communication will be managed on-site, including designated signal persons, radio channels, and reporting structures.

- **Permits and Compliance:** List all necessary permits (e.g., road closures, special permits for oversized loads) and ensure compliance with relevant industry standards and local regulations.

- **Responsibilities:** Clearly define the roles and responsibilities of each party involved – client, contractor, equipment supplier, and on-site personnel.

Having a clear, structured document like this ensures that every element of the lift is considered and planned for, significantly reducing the chances of miscommunication or oversight. It becomes an indispensable tool that everyone can refer back to, fostering transparency and accountability throughout the project lifecycle.

Ultimately, investing time in creating a robust and detailed Scope of Work template for your lifting operations pays dividends in terms of enhanced safety, operational efficiency, and overall project success. It transforms complex, high-risk tasks into manageable, well-orchestrated processes. By standardizing your approach with a comprehensive template, you’re not just planning a lift; you’re building a foundation for consistent excellence and peace of mind in every operation.